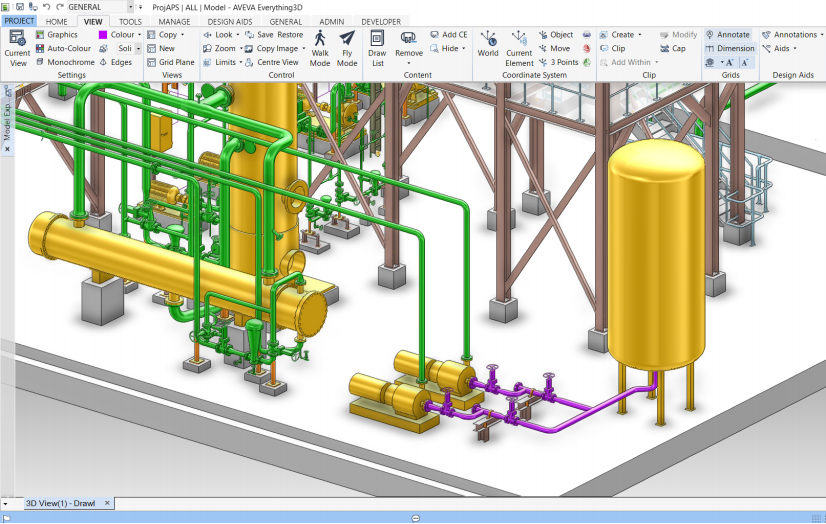

Performing consulting services for electrical instruments and industrial automation

In today’s world, due to the expansion of information and technological advances, every branch of science and industry needs the necessary experience and technical knowledge to prevent extra costs in the implementation of industrial projects and also to achieve the ultimate goal quickly considering cost benefit issues to be done more efficiently. The issue of consulting is one of the most important issues in the implementation of industrial projects that factory managers often think of consulting in times of crisis, which is a shortcoming. However, if the use of specialized consulting services is obtained in a timely manner, it will help the employer to achieve its goals by having the following benefits:

- Inspection

- Price Control

- Effective periodic controls

- Principled and professional design

- Accelerate the achievement of the final goal of the project

- Preparation of computational and engineering micro-information

- Basic and preliminary feasibility studies

- Professional negotiations to resolve professional disputes

- Cost forecasting with cost-benefit estimation approach

- Balancing the relationship between the investor and the sellers of equipment and machinery

Providing consulting services for the purchase of industrial machinery from the perspective of the control system and PLC

Due to the fact that the control systems of industrial machines have made significant progress recently, so the purchase of these machines has become a specialty. In this regard, the consultant engineer plays a very important role in meeting the technical needs and operation of the employer and vendors of machines, and if the purchase of equipment and delivery is done with the help of an experienced person, the benefits are subject to the owner of factory in the long run.

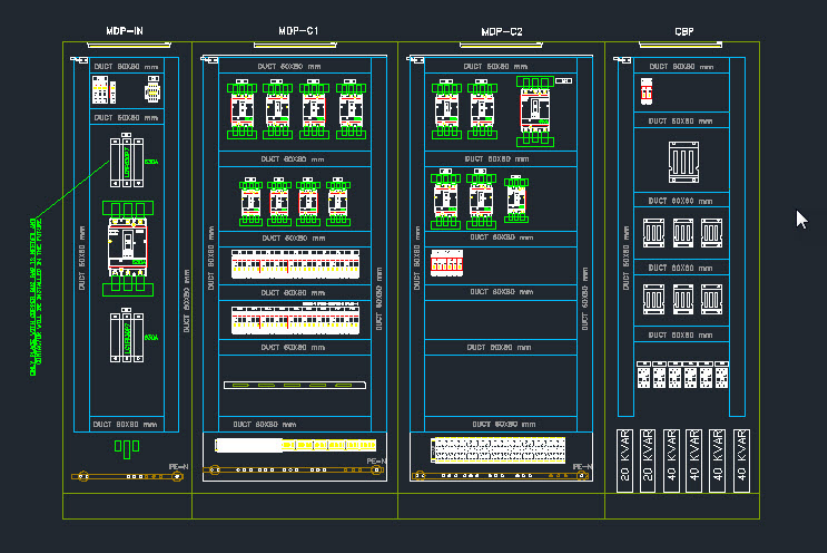

Design (electrical drawings including L.V and M.V – Instrumental and P&ID – specialized industrial electronic boards)

The factory’s electrical system and electrical installations can be compared to the blood supply to its heart. If this issue is done unprofessionally and non-engineering by unqualified people at the beginning of the design, the employers will face many problems until the end of operation. Therefore, one of the main concerns of employers is the preparation of electrical drawings and MCC panels and the distribution of machinery or other consumers in industries. With the increasing price of electrical equipment, the need for optimal design and selection of parts and assembly of electrical panels in accordance with the required specifications is felt more than ever. Our consulting team is ready to serve in this matter and we have been cooperating with prominent panel manufactures for several years and we will be proud to be with esteemed employers in consulting, designing and coordinating the construction of low voltage, medium voltage, and control panels based on PLC & HMI.

HMI – PLC – SCADA systems programming

What is PLC? PLC stands for Programmable Logic Controller, which in today’s industry plays an important role in controlling various systems in the industry and replaces command circuits and brings valuable benefits to system users.

Some manufacturers of such equipment are as follows:

Allen Bradley PLCs (AB)

Siemens PLCs

Mitsubishi PLCs

Omron PLCs

Delta PLCs

Modicon PLCs

Honeywell PLCs

Schneider Electric PLCs

Our main expertise is in the field of Siemens PLCs, which have taken the second place in the world and by benefiting from suitable hardware and high-performance software, especially the integrated PCS7 control system, have been able to have a suitable market share in the industry

Preparation of technical documentation before and after implementation (Basic Design & As Built)

Cable calculation according with international standards such as IEC 60364-5-52

Preparing the tray and ladder path drawing

Preparation of Material Take-Off equipment list

Preparing the PLC, I/O list- Terminal Strip- Termination reference documents

Execution monitoring (project control, testing and FAT delivery) in the field of electrical and control

Design of storage tank weighing systems

Today, Load cell-based weighing systems are playing very important role in the systems for measuring the weight of tanks and hoppers, moving conveyors (Belt Scale), and therefore designing and observing engineering principles and selecting the right equipment according to the use and location of the most important priority.

The effective factors in selecting a load cell include the following:

Type of mounting

Load cell core

Load cell height

Further curvature above the load cell

Large load cell floor

Load cell weight

Desired working weight

Maximum tolerable weight

Design and calculation of lightning arresters based on NFC17-102 standard

Lightning arresters play an important role in high-rise buildings and factories and infrastructure facilities where sensitive electronic and electrical equipment is used, as well as to protect the building itself from lightning strikes and rapid discharge of electrical energy with very high voltage and current. Selected without accurate and non-expert calculations will not work properly and will waste employers’ costs.So ask us for help in choosing the technical specifications, brand, required number and even expert price.

Lighting design and calculations

Today, due to rising energy prices and the variety of lighting fixtures and related electrical systems, engineering calculations with software such as DIAlux leads to optimize and increase the reliability, aesthetics and pleasant environment, high efficiency of the lighting system is essential. This consultant is proud to work with well-known companies such as Mazi Noor in this regard and offers various solutions in this regard for respected industries.

Why use our services?

We offer the most professional comprehensive solutions at the lowest cost for small and medium projects. Because in larger projects, the need for consulting engineers is often felt, but in smaller projects, the use of knowledge and expertise, engineering ability, experimental approach and cost reduction to high productivity are considered by industry owners. So do not worry, we are a group of capable engineers who have learned the knowledge and principles of project engineering together in large and medium projects, especially oil and gas-steel-chemical industries, for years, and now we share it with esteemed employers.

So if you are planning to build a factory or a project, there is no need to worry about electrical, instrumentation and control issues. Contact us first. We will be at your service.